Research and Technical Service

Research and Technical Service

Since the Industrial Revolution, the massive use of fossil fuels accompanying the increase in energy demand, the strond food demand due to the population increase worldwide became obvious, securing sustainable energy source and prevention of global warming has been discussed as urgent issues. Although it is not easy to derive a solution, it draws on its realization with diversification and effective utilization of energy.

In Meiwa Co., Ltd., we are working on Research and Development while gathering and fusing all the technologies from the past to the most advanced, looking at the next generation.

Examples of Industry-academia-government

collaboration project

Main Industry-academia-government collaboration projects

| Our technology | Cooperation partners |

|---|---|

| Pentagene system (Pyrolysys of woody biomass and poultry feces) | Tokyo University Tokyo Institute of Technology |

| Rapid pyrolysis and bio oil (Circulating fluidized bed · Auger type) | Tokyo University Japan Advanced Institute of Science and Technology National Institute of Advanced Industrial Science and Technology |

| Methane fermentation (Fuel cell / bio oil) | Kanazawa University Public Works Research Institute Kyushu University (Fuel cell / bio oil) Tottori University of Environmental Studies |

| Progressive-Freezing-Concentration | Ishikawa Prefectural University Industrial Research Institute of Ishikawa Ishikawa Agriculture Research Center |

| Decontamination | Tokyo University (for Soil) Tohoku University (for Bark) |

| Gasification of charcoal | Tokyo Univerisity (for Cogeneration System) Tokyo Institute of Technology (for Disaster Support System) |

| Bio oil · wood vinegar solution | Kagoshima University |

Detail.1Methane Fermentation

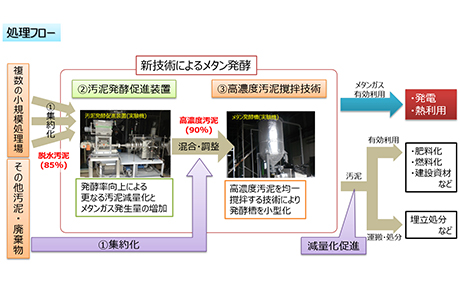

Meiwa Co., Ltd. participated in Ishikawa prefecture's "methane emission control technology review committee" in FY2011, was entrusted with the project "Technology development of mixed high efficiency methane fermentation of garbage and herbaceous biomass" from the Ministry of the Environment in collaboration with Kanazawa University and several companies in FY2013, participated in the joint research "Research on effective utilization of methane gas suitable for small scale processing facility" in collaboration with Public Works Research Institute, Kanazawa University and several companies in FY2014. After the R & D, Meiwa Co., Ltd. completed the development of the methane fermentation.

Technology development of composite high efficiency methane fermentation of garbage and herbaceous

biomass (2 years project)

-

Implementation flow

-

Methane fermentor

Effective utilization of methane gas suitable for small-scale processing facilities (one year project)

In FY2014, it was implemented at Chubu Clean Center in Naka Noto Town.

-

Methane Utilization Ishikawa Model Process Flow

-

Test scene

In-house test (30 m3 scale tank, FY2015 and later)

Development of stirring mechanism under high viscosity digested sludge condition in highly concentrated raw material.

Construction of regional energy circulation system combining high efficiency fuel cell and regenerative biogas

(Science and Technology Research Partnership for Sustainable Development, Japan Science and Technology Agency).

Re-entrusted from Kyushu University, we started business from FY2016 and installed bench-scale methane fermentation system at the end of FY2017

Medium Noto-machi Biomass Methane Fermentation Facilities Mechanical Electrical Equipment Construction

Designed and installed a methane fermentation tank of 300m3 scale in CY2017. The feedstock for the methane fermentation supplied to the tank from April, 2017 and the continous operation commenced from October, 2017. It has been in operation since then.

Detail.2Gasification of Charcoal

We, Meiwa Co., Ltd. are currently confident that we are the top runner in the pyrolysis machinery market of Japan approximately 20 years after a pyrolysis equipment was installed as a demonstration one at the co-drying facility of JA(Japan Agricultural Cooperatives) in Komatsu city in 1996, starting with rice husk carbonization. Along with the recent promotion of the use of renewable energy and the increase in the number of power producers because of FIT (Feed-in-Tariff), the pyrolysis technology has gathered attentions as biomass gasification. However, there is still issue existing that the tar produced from biomass by pyrolysis makes bad functional effects on various devices in an equipment, and everyone agrees that it is recognized as a major technical issue.

Therefore, we regard and treat pyrolysis as pretreatment, and focus on technology to gasify charcoal produced in the pyrolys process, and in recent years we are carrying out empirical research as "gasification of charcoal". Since most of the charred materials are carbon, the composition of carbon monoxide, carbon dioxide, and nitrogen is almost unchanged in the gasification gas, and substances like tar are also not produced as byproducts.

As part of the cogeneration system from Tokyo University for three years from FY2015, we got a contract for charcoal gasification equipment (batch type), and conducted a demonstration test on the farm in Katori city, Chiba prefecture. in FY2017, we got a contract to design and produce larger continuous charcoal gasification system from Tokyo Institute of Technology.

From the project ordered from the University of Tokyo

-

Demonstration Plant (Green House)

-

Gasifier

-

States of Charcoal Gasification

Testing and Analysis Service

Meiwa Co., Ltd. sets up test and demonstration equipment in the test building, so that we can respond to customer's individual needs uniformly, and we are developing products. For example, it is possible to test using the following equipment.

- Carbonization equipment (batch type, rotary type): Carbonization of various biomass and

brown coal, generation of wood vinegar - Gasification power generator: gasification of charcoal, wood chips, pellets and dry chicken feces

- Expansion softening equipment: reforming of rice husk, etc. and its performance evaluation

- Progressive freezing concentration machine: Concentrate sake, flavor, milk, fruit juice, etc.

- Bio oil production equipment: generation of bio oil

- Agricultural utilization of charred materials: Analysis of various components and cultivation

test (field or pot test of in-house or third party organization) - Thermogravimetry Analysis

Any various examination and inspection at our company is feasible if you consider effective use of resources and waste disposal. Please feel free to contact us if you have any inquiries on our technology.

English

English 日本語

日本語 中文

中文